style / Big Shirt Two

cloth / Natural Hand Dyed Check

Price /

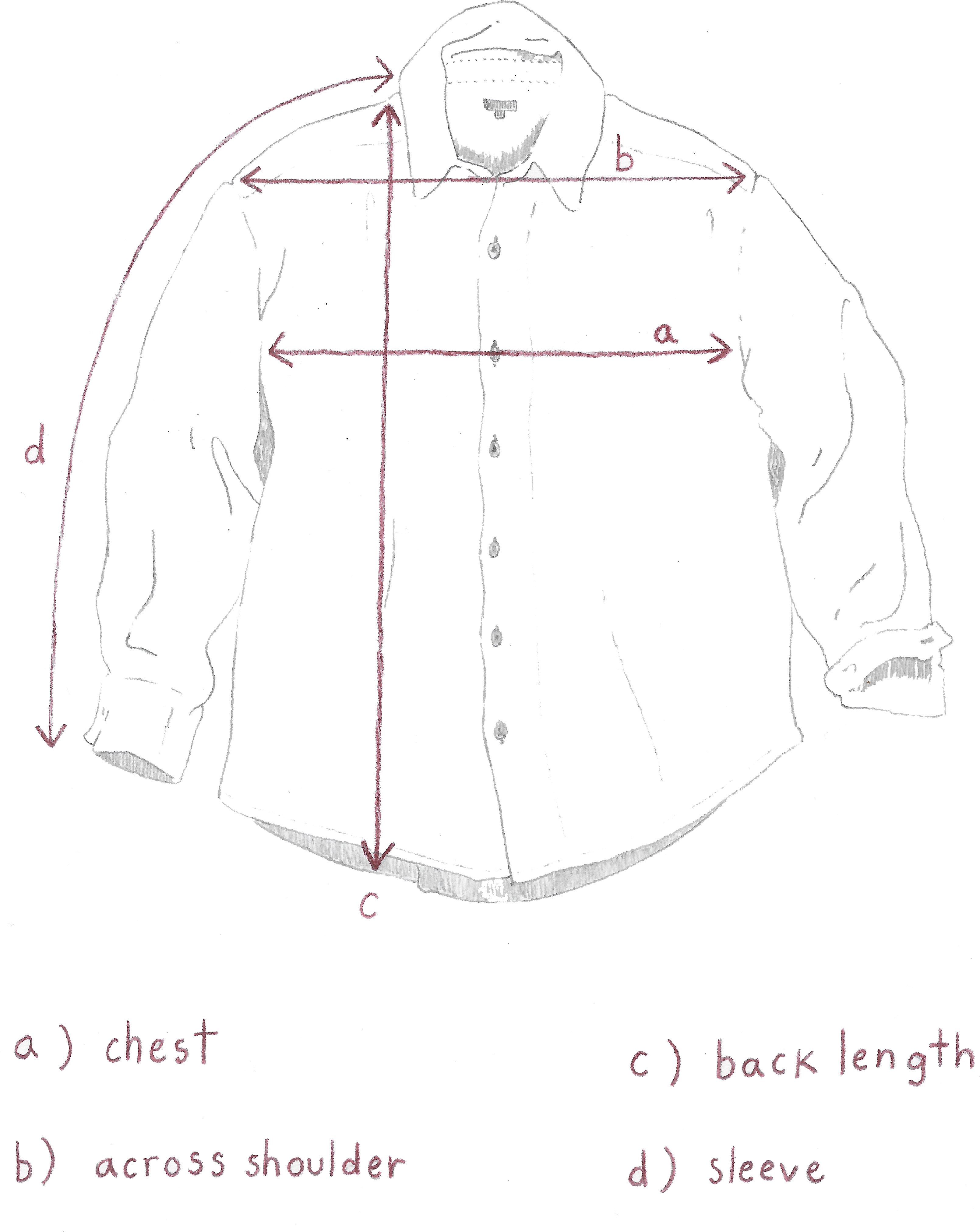

A looser fitting buttondown with single chest pocket, corozo buttons, french seams, squared cuffs, pointed collar, more pronounced curved hem and ‘invisible’ placket. This shirt is based on the same fit of the Big Shirt - cut more relaxed in the chest with a dropped shoulder and a slightly longer body compared to the Two Pocket Shirt.

Hand numbered edition made in California.

For over a thousand years, persimmon dyeing has played an important role in Japanese crafts. It was traditionally used to protect materials against water, moths and unwanted odors. Fishing nets, Sakabukuro (sake filter), umbrellas, garments, and even wooden buildings and furniture were coated with persimmon tannin for the added durability and protection. Persimmon dyeing is very colorfast - it doesn’t come off or fade easily like indigo or many other natural dyes. By contrast, the color of persimmon dye grows deeper over time, especially after being exposed to sunlight - lighter brown will eventually grow to a darker, richer brown.

The persimmon tannin used for this fabric comes from locally harvested ”Fuyukaki” (a strain of astringent persimmon from Mizuho in Gifu, where the dyeing took place). The 100% natural persimmon juice is fermented for a minimum of three years before it is used. From the harvesting of persimmon to the final dyeing process, each and every step is done by hand, using no electricity. The juice is diluted with water, to dye the fabric multiple times to achieve a deeper shade. By creating multiple layers of color over time, the fabric is more colorfast and less stiff - to create a long lasting color requires a minimum of 4 or 5 times of dyeing and drying in the sun.

This process is highly dependent upon nature - making each piece a unique expression of the sunlight on a given day. The cloth varies in pattern and hue not only due to the weather, but also the way the linen absorbs the persimmon tannins and reacts with the iron mordant. Even further, when they are cut and sewn (and kept within similar color groups as much as possible) they feature a great deal of variation and irregularity - some of which will lessen over time as the garment is worn in the sun and washed, darkening and settling the color.